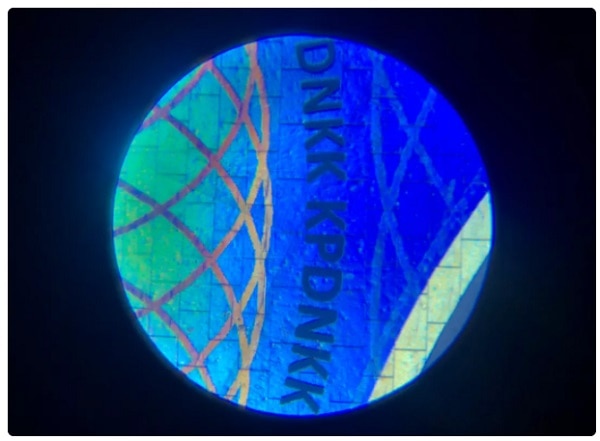

The production of micro-nano structural colors requires multiple exposures on the photo-resist material to form a complete pattern. Most of these patterns are composed of a pixel array structure spliced together, and they can also be a vector line structure. But all require millions of photolithography exposures.

The manufacturing of micro-nano structural colors can be divided into dozens of steps depending on the final product. From pattern design to mass production, there will be differences depending on the process.

In a dust-free environment, the dot matrix equipment ensures the regular accuracy of the micro-nano structure through tens of thousands of precision controls. In this process, air cleanliness and temperature, humidity control must be strictly controlled.

How to Make Micro-nano Structural Color

Here are 9 key tips to make the micro-nano structural color, including design, photo-resist coating, exposure, developing, hard film, Combination Plate, metallization, molded, and reel packaging. Each step is quite important.

Design

The first step in making micro-nano structural colors is to design the final desired color texture, and brightness and take into account the observation field of view, distance, light source and the influence on the structural color.

Photoresist Coating

Before photolithography, the photosensitive material “photo-resist” or “photo-resist” must be uniformly coated on the photo-resist carrier (glass used here), and the wafer is placed in the photolithography machine after drying.

Exposure

On the photo-resist plate, the stripe structure of different frequencies, different directions, and different brightness is recorded by exposure (generally divided into interferometric and direct writing. At the same time, the light beam of the lens chemically reacts with the photo-resist, so that the pattern in the computer is printed on the photo-resist coating.

Developing

After the lithography machine stops processing, if there is no secondary processing, the photoresist plate can be removed, and the photo-resist in the exposed area is washed away with a dedicated developer (positive photo-resist is used here), and the photo-resist should be kept dry. Prevent falling ash and moisture.

Hard Film

After the photo-resist is developed, it must be baked to permanently fix the formed structure.

Combination Plate

For mass production, most structural color products must be assembled except for patterns that require large-area lithography. They can be divided into hot-pressing and UV grouping. The grouping must conform to the package roller and the width of the package and take into account the tension and shrinkage of different materials.

Metallization

The diaphragm needs to be metalized twice. the first time is the surface metallization and the second time is the metal mold. The thickness of this kind of metal mold is generally about 70um.

There is another way to make the diaphragm after the plate assembly does not need to be metalized. However, it has not become the mainstream because it is difficult to completely solve the problem of material deformation and alignment.

Molded

The metalized micro-nano structures can be transferred to the film material covered with the information layer by hot pressing, or by cold pressing.

Reel Packaging

The last step is to encapsulate the film with microstructures. Next, you need to match different production processes to make different types of products. For example, processes such as coating, printing, and aluminum washing can be linked.

Structural colors can express colors through diffraction and reflection. Most micro-nano structural colors need to go through tens of thousands or even millions of exposures, and have extremely high requirements for the stability of exposure power, requiring micro-nano precision to mutual nesting.

Sometimes, it is necessary to make a structure with a slope on the surface of the photoresist. The purpose of this is to increase the reflection and expand the field of view.

Quality Assurance of Micro-nano Structure

You know, no matter how small the dust is, once it falls on the photoresistplate, it will damage the plate. Therefore, how to ensure the yield of production, the cleanliness of the clean workshop is very important.

The air in the clean workshop is continuously filtered and circulated. Employees need to wear special work clothes to maintain a low-dust working environment.