There is a kind of bird in western North America called Anna’s Hummingbird. When it “shakes its head” on the branch, its head and neck feathers will constantly change colors. In fact, the secret of Anna’s Hummingbird’s face changing lies in the feather structure of its head.

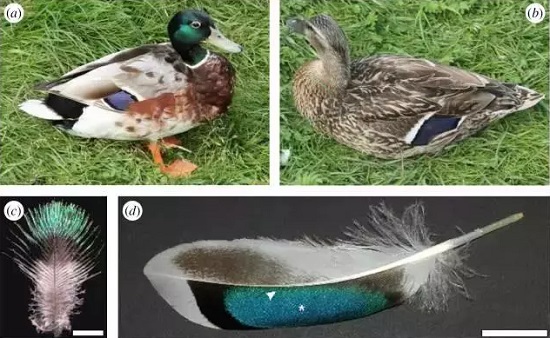

In fact, from a specific angle, many bird feathers have distinctive bright colors, such as the green on the head of a mallard and the blue-green on the body of the magpie. But if you look at it from another angle, these colors will change or completely lose their metallic luster.

Feathers with the above characteristics are structural colors. They are not formed by pigments, but the unique sub-microscopic physical structure of the feather surface makes the incident light scatter, refract, and multi-layer interference, thus producing a metallic “iridescent luster”.

Structural color is the color formed by the change of light propagation direction caused by some special microstructures, and it is an optical effect formed by the micro-nano structure.

Micro-nano structural color based on the principle of physical optics to process materials into micron-scale periodic structures. It is affected by the size and period of the structure and can scatter light of a specific color onto the surface of the material under the irradiation of white light.

Micro-nano structural color will be the safest and most environmentally friendly color expression method in the future. Its unique color-forming principle gives it unique characteristics, which are mainly reflected in the following three aspects:

1, Bright colors and high saturation

Optical structural colors have strong wavelength selectivity, so the display of specific colors can be achieved by controlling the surface structure of the material. Traditional drawing or screen display is generally based on a three-primary color mixing solution, that is, through proper matching, various other colors are constructed, but this color forming method is essentially a kind of “false color”.

The optical structural color is different from traditional drawing or screen display, it can scatter any high-purity color according to the needs, and achieve true “full color” so that the display effect is more bright.

2, Eco-friendly, no fade

The production of optical structural colors is based on the processing of raw materials on a microscopic scale. General manufacturing techniques include electron beam lithography, magnetron sputtering radio frequency method, vacuum nano-evaporation method, solution coating method, and physical deposition method.

These processing methods completely abandon the traditional coloring method using dye vat or paint, and by improving the properties of raw materials, the optical micro-nano structural color can be more durable to deal with harsh environments such as strong light radiation and acid-base corrosion.

Therefore, the surface processed by using micro-nano structural color can not only maintain the original luster for a long time, but the production process can greatly reduce the harm of chemical paint to the environment and human body.

3, Controllable Colors

Different from the characteristic of chemical dyes that “color is fixed”, micro-nano structural colors use the influence that the tiny structure of the material surface to the light beam to realize the display of different colors.

Because the tiny unit in the structural color can make the light wave scattered by the material surface be flexibly controlled through external force deformation, electromechanical control, and other means, In particular, the small structural units arranged in cycles.

At present, micro-nano structural colors are being used more and more widely in product design. As social development, Product designers are not only concerned about the traditional colors, materials, and product processing, but also better pay attention to the decorative texture effects and green eco-friendly of product appearance.

This is because consumers have higher expectations for the beauty, visual appearance, and consumer’s user experience of the product’s structural color.

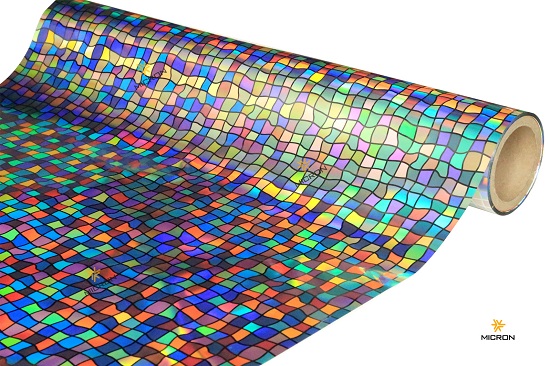

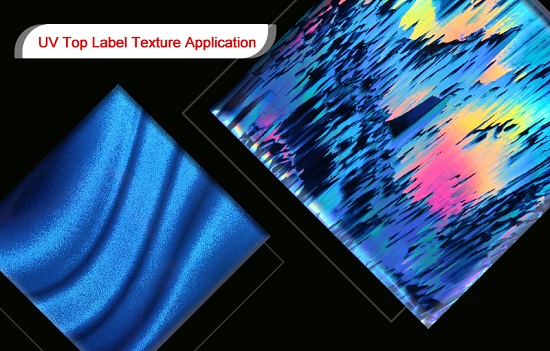

The team of Suzhou Image Laser Company expanded its holographic technology and developed a micro-nano structure film material using this technology, which we call micro-nano texture. It can present various texture patterns and rich colors without pigment, printing, and other processes.

The micro-nano texture film adopts holographic technology to display various texture graphics, natural texture effects, light and shadow changes, etc. It has the characteristics of environmental protection and low pollution and is suitable for IMR, IML, IMF, and other plastic IMD. It can be widely used for surface decoration of electronic appliances, architectural decoration, leather cloth of luggage, sanitary ware, etc.

If you are interested in micro-nano textures, please visit the following more related articles.